Freezing Weather & Oil Spills

Happy New Year and welcome to 2022! Just because it’s almost the end of January, doesn’t mean we’ve seen the last of our cold weather, yet. As the winter months continue, it’s crucial to remember the damage freezing weather creates on pipelines to sustain a proactive response plan in the event of a spill. “Frost Heave,” the leading cause of cold weather damage, is the upwards swelling of soil during freezing conditions. This has accounted for 82% of all cold-weather pipeline incidents in the United States from 1984 to 2020. The second leading cause, at 11%, is the accumulation and movement of snow. Freezing weather oil spills are common during this time of year. Because these conditions cause such a high rate of damage, we wanted to provide our customers with some information and tips on how to best combat this over the remaining winter months!

While there’s no single cause to point to prevent all oil spills from happening, we do know weather plays a significant role in determining the outcome of these incidents. Oil spills are more common than the average person might think, and monitoring activities reduces the likelihood of pipeline damage. Contingency plans involving OSRO certified response teams and quality containment/clean up products will stop a spill and get it cleaned up quickly when done so correctly.

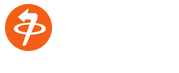

Demonstration of Frost heave on Buried Pipeline (Credit: https://www.sciencedirect.com/science/article/abs/pii/S0165232X18301034)

Understanding Weather and Pipeline Damage Correlation

Did you know that average daily temperatures are actually not the best indication for pipeline system damages? There is actually a much larger correlation between “Freeze Days” – the number of days that the high temperature was below 32 degrees F – and pipeline damage than daily temperatures. Additionally, 90% of damages occurred after just FIVE freeze days. This is because freeze days can lead directly to frost heave. As long as there is enough unfrozen water supply to keep feeding the formation of these ice crystals, the damage will continue to grow.

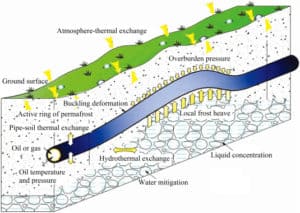

The two most common criteria for freezing susceptibility in the soil are when more than 10% of soil particles are finer than 0.075 mm or when more than 3% of particles are finer than 0.020 mm. This means that silty and loamy soil types are going to be the most susceptible to frost heave. This is because they retain moisture and have a fine enough particle size to allow for expansion.

Map of Water Storage & Soil Composition in the United States (Credit: https://earthobservatory.nasa.gov/images/87220/soil-composition-across-the-us)

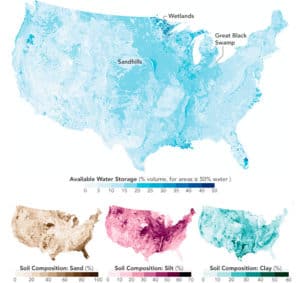

The Midwest United States has a high percentage of this soil and has some of the highest available water storage of any other U.S. region. This area of geography also has 19,525 miles of crude pipelines and 152,160 miles of product lines running through it. Additionally, from 2016-2020 there was an average of 61 freeze days logged across 34 major Midwest cities. As mentioned above, 90% of pipeline damages occurred after just five observed freeze days.

Outside of these, there are several other factors that can and do contribute to pipeline damage in freezing weather. Certainly, not every underground pipeline is subject to the same level of susceptibility from these but being aware of each can help build a better understanding for your environment. We’ve already discussed which types of soil are most likely to form frost heave, but according to the Pipeline Hazardous Material Safety Administration (PHMSA), pipeline depth, material, age, and the size itself all play a part in the potential damages that come from freezing weather.

Pipeline Depth and Size

Since the biggest issue with cold-weather damage is frost heave, the depth that pipelines are buried plays a huge part in whether these are pushed towards the surface. The deeper a pipeline system is buried, the less likely they are to be damaged from frost heave. Most of the movement from this occurs closer to the surface since this is usually a finer soil-type and it is more exposed to the elements than lower layers. Additionally, smaller diameter pipelines are going to be more susceptible to cracking and breaks due to their lack of surface area. The Gas Technology Institute (GTI) researchers have determined that pipelines with a minimum diameter of 18 inches were far less likely to have breaks. In-fact, of the samples they observed, none of the pipelines with this diameter or larger had any breaks.

Petroleum Pipelines Across the Midwest (Credit: https://www.energy.gov/sites/prod/files/2015/10/f27/Energy_Sector_Risk_Profile_MidwestRegion.pdf)

Pipeline Age and Material

It may come at no surprise that the older an object may be, the more likely it is to sustain damages. However, what also contributes to this is the implementation and usage of sturdier materials after 1950. Any pipeline older than this will have a disproportionately high susceptibility to freezing conditions as the steel of this era has a much lower quality of ductility towards low-temperatures. Any pipeline constructed of steel or iron (whether it be cast-iron or wrought-iron) is going to be more likely to break as opposed to those constructed from plastic or other materials. The methods used to combine these early-era pipelines to one another also proves to be inferior to modern advances. These lack of advances cause splitting and breaking at the source of these seams.

Since we can’t pinpoint a single factor to look to for all of the oil releases across the country, every potential variable should be considered and have a plan determined for it just in case. Cold weather is no different. Anyone who owns or operates near gas infrastructure areas that have these variables should be acting now to increase reliability in the future.

Having a response team capable of responding quickly to your area is imperative. Additionally, maintaining proper spill response equipment on-site can help prevent excess damage while waiting for these teams to arrive. Save time and money in the event of these spills by having a response trailer or container filled with containment boom, sorbent boom, secondary containment, spill kits, and more.

Contact the Professionals

Call us or contact us through our website today and learn how you can be better prepared for the upcoming months with our OSRO Certified, 24/7 Emergency Response services and the quality containment products we’ve been offering since 1967.

Shop Our Complete List of Products

Want More Information on Oil Spills?

Here are some our other articles you might be interested in:

Oil Spill Response

Oil Spill Cleanup

Containment Boom Users Guide

Know Which Product You Need? Request a Quote, Now!

Request a Quote - Products Form

Request a Quote - Products Form

Sources

https://www.energy.gov/sites/prod/files/2015/10/f27/Energy_Sector_Risk_Profile_MidwestRegion.pdf

https://www.bls.gov/regions/midwest/midwest.htm

https://www.noaa.gov/education/resource-collections/ocean-coasts/oil-spills

https://earthobservatory.nasa.gov/images/87220/soil-composition-across-the-us

https://www.ptac.org/wp-content/uploads/2016/08/parsc-003-vol-2-final-appendices-signed.pdf

https://www.sciencedirect.com/science/article/abs/pii/S0165232X18301034