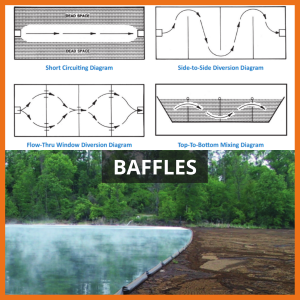

Baffles

Specifications:

ACME baffles create side-to-side or flow patterns that increase retention time and eliminate short-circuiting or channeling. Top-to-bottom flow patterns can also be created for a turnover effect.

Baflles can be easily relocated within a lagoon as needs or conditions change. Flow-thru windows can be added, relocated or modified for any flow variation, helping control flow and circulation, eliminate dead zones, and improve efficiency.

ACME floating baffles are manufactured from a variety of flexible thermoplastic coated (not laminated) reinforced fabrics. The fabrics are dielectrically sealed to form enclosures for the flotation logs, chain ballast and optional cable tension members. These items are connected with the floatation logs at the surface and the chain at the lagoon bottom. Tension cable(s) are sometimes included in our floating baffles to provide added strength and eliminate arcing.

ACME custom-manufactured floating baffles offer an easy, flexible, economical way to improve the efficiency and effectiveness of lagoons. Floating baffles help facilitate surface control of floating materials in cooling ponds, settling basins or oxidation ponds.

Because ACME floating baffles are fully customized to meet specific needs and applications, we do not keep them in inventory. To calculate the cost of your specific need, simply send us the specifications for the design you have in mind. We’ll get back to you promptly with a quote.