There are five basic types of operational boom failure:

- Entrainment

- Drainage

- Splash over

- Submergence

- Planning

While oil spill containment booms are very successful in collecting oil on water for recovery, their effectiveness is limited in certain applications. These failures all occur while all of the boom components are intact and functioning together. A structural failure is separate from an operational failure.

Entrainment occurs at current velocities between 0.7 and 1.0 knots. Oil droplets escape under the boom due to the headwave upstream of the boom and turbulence at the downstream side of the head wave. The amount of oil lost depends on the thickness of the oil in the headwave. ACME recommends that a secondary (“backup”) boom be deployed to collect any oil droplets that may escape under the oil spill containment boom.

Drainage failure is the rarest failure of the five. Drainage typically occurs when small oil spill containment boom is used and too much oil causes the soil to flow down the face of the boom and exit on the other side. Similar to entrainment, drainage failure involves leakage from large pools of oil that are collected by the oil spill containment boom. In order to prevent drainage failures, deploy skimmers in the large areas of oil or place sorbent mats on the upstream side of the oil spill containment booms. These steps will allow for the large pools of oil to be removed prior to drainage failure.

Splashover may occur in choppy water when the wave height is greater than the freeboard of the oil spill containment boom. Splashover often times occurs when the wave length to height ratio is less than 10:1. ACME recommends that a secondary (“backup”) boom be deployed to collect any oil droplets that may escape over the oil spill containment boom.

Submergence may occur when a boom is deployed or anchored in a fast current or is being towed at a high velocity. Submergence is not common as entrainment failure usually occurs prior to the speed needed for submergence.

Planning failure is a common failure when strong wind and current are present in opposite directions. This failure is most likely to occur when the oil spill containment boom has inadequate ballasting or when internal tension member is near or above the waterline.

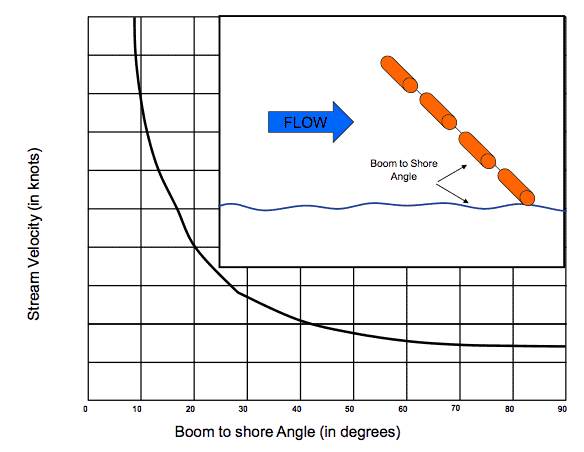

Oil spill containment boom performance depends on the angle between the boom and the current. As can be seen in the graph below, the angle of deployment decreases as the current in the water increases. The boom angle allows for the velocity of the current to be reduced perpendicular to the boom.

Often times a flexible boom will become more like a J-shape when the angle with the direction of flow becomes small. The portion of the boom that is curving across the direction of flow will be the part of the oil spill containment boom in which is the likeliest to fail. ACME advises that this portion of the boom be maintained and checked in the event of increased current or wind.

Want more information on boom failures? Contact us today with your oil spill containment boom question or request.